All About D2 Tool Steel

Perhaps you have been scanning your favorite social media site or online marketplace and realized that many of the ‘Cooler-Looking’ knives are stamped with the letter ‘D’ with the number ‘2’ directly beside it. “What the heck does that mean?” “Is it a brand I’ve never heard of?!” Nope. You, my internet friend, have just stumbled upon one of the best steel formulations ever discovered.

D2 tool steel is a high-carbon steel that is widely used in the knife industry. It is often regarded as a ‘super steel’ due to its exceptional properties and heavy-duty applications, which make it suitable for a wide range of real-world purposes. They don’t call the stuff ‘Tool Steel’ for no reason. So, let’s get into the history, characteristics, and properties of D2 knife steel, and by the end of this article, you’ll know EXACTLY WHY they call D2, THE ‘Tool Steel’.

History of D2 Knife Steel

D2 knife steel is a high-carbon tool steel that was first developed by Crucible Industries in the late 1970s. It was designed to be hard and tough, with excellent wear resistance, and was marketed as a superior metal for cutting tools and knife blades. Knife manufacturers quickly took notice and their customers quickly caught on to the wonders of this miracle steel. For decades, since its initial introduction to the market, D2 steel has become one of the most popular materials for knife manufacturers, mainly due to its INSANE ability to hold an edge for extended periods of time.

Characteristics and Properties

D2 tool steel has several excellent characteristics that make it a popular choice for knife makers and the users that purchase these knives. This ‘super steel’ is known for its exceptional wear resistance, edge maintainability, and its ability to sustain unorthodox maneuvers, such as being used as a pry bar or batoning. D2 steel is also highly resistant to corrosion, thanks to its high chromium content, which makes it suitable for use in wet or brackish environments. It really is a ‘super steel’.

In addition to its wear resistance, D2 steel is also known for its overall toughness, which makes it suitable for use in hard-use tasks such carving. What I am really trying to get at here, is that D2 is a ‘no joke’ steel that can take a SERIOUS beating. Surprisingly, it is also relatively easy to sharpen and suitable for everyday carry tasks such as opening packages or cutting steak.

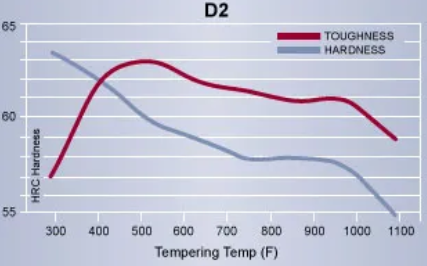

The hardness of D2 ranges from approximately 58-61 on the Rockwell C scale, making it particularly suitable for use in heavy use and outdoor survival tasks. However, it should be noted that the hardness of D2 steel, or any steel for that matter, can vary depending on the heat treatment process used by the manufacturer. So, always make sure to buy from a quality manufacturer such as Benchmade.

Another advantage of D2 steel is that knife makers have found it easy to work with, making it suitable for use in a variety of knife patterns and designs. Due to the high carbon content, the steel formulation allows for the creation of different finishes, such as a hamon, which is a popular Japanese blade finish that uses a combination of clay with a specialized heat treatment in order to create a distinctive patterning on the blade itself. The bottomline is that you really can’t go wrong with D2 tool steel. It is a wonderful ‘super steel’ with a variety of uses. Thank you for reading.